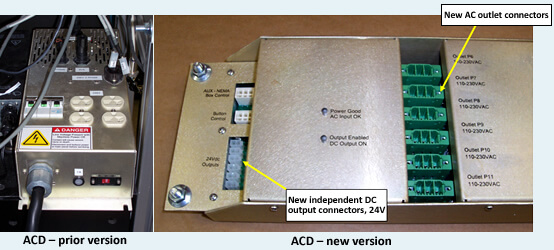

The newly redesigned Trion Technology AC distribution module makes use of a printed circuit board to house the various components and thus eliminates 90% of the wiring that had been required previously. This increases the reliability and durability of the module.

The design now also incorporates MOVs (metal-oxide varistors) to give the circuitry surge protection. The new design increases the single-phase outlet connectors from four to six to more readily power the various components used on the system such as turbo pumps, RF generators, etc. Each of the six outlets has its own dedicated fuse.

A new single 24Vdc power supply capable of delivering up to 500Watts has replaced two independent power supplies. This is an increase of about 250Watts. In addition, there are now six output connectors for the 24Vdc power. This allows easier and cleaner cabling to power the various devices that need 24Vdc on the tool.

The AC distribution can be built up in either single-phase or three-phase configurations, depending on the power requirements for the equipment on the tool.

Click Here to Close

Many Trion Technology Customers have found that proper maintenance of their Trion system is fundamental in optimizing uptime, reliability, and repeatable process performance.

To improve Trion’s support to you and to give a better advantage of improving the performance of your Trion system, we are pleased to offer our Annual Preventative Maintenance program.

This Preventive Maintenance program includes a comprehensive inspection of your system along with

the following activities:

The PM will be performed at a mutually agreed upon date with Trion recommending appropriate alternate dates for your convenience. The primary factors determining the ideal schedule include system age, process gases, usage level, and the amount of time since the last preventive maintenance service was performed.

Trion Technology will also provide a specific list of parts to be inspected and if necessary, replaced. Trion will ship applicable parts (PM Kit) to your facility two weeks prior to your scheduled PM.

This program will enable Trion to collect and maintain baseline data specific to your Trion system. This data can be valuable as a troubleshooting aid for your company should you see a process shift due to a defective or drifting component. It can also be used as a guide to possible upgrades and retrofits that are available for your system to increase performance and improve process specifications.

If you have any questions or would like more information concerning this program please do not hesitate to contact us at service@triontech.com.

Click Here to Close

Trion Technology Customer Service Department has recently gone through a restructuring in order to be more responsive to our customers.

We have relocated the service coordinator position from Tempe, Arizona to our corporate office in Clearwater, Florida. This will help ensure a faster turnaround with communication and coordination within our service department.

Kapri McKenzie is our new service coordinator. She handles processing service quotes, service contract quotes, RMA requests, purchase orders, customer surveys and warranty forms. Along with these duties, Kapri fields incoming technical calls to help route them to an available technician.

Kapri can be reached from Monday – Friday, 8:30AM – 5:30PM EST via:

Phone: 727-447-1110

Fax: 727-447-1581

Email: service@triontech.com

Website Form: https://triontech.com/service/

When contacting us, please include your company name and the tool serial number, which will help us expedite your service needs.

Trion Technology is deeply committed to improving overall customer satisfaction. We would like to hear from you directly with suggestions and comments. Let us know how we can do better.

Please forward this letter to others who may need to contact our Service Department.

Click Here to Close

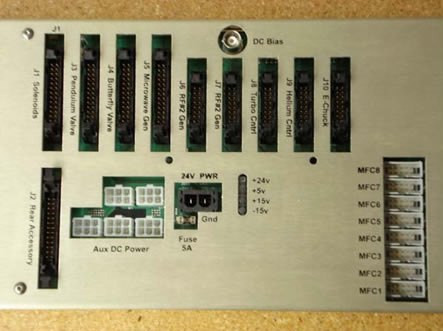

Trion Technology introduces a new PLC design as part of our continuing quality improvement program.

Trion Technology introduces a new PLC design as part of our continuing quality improvement program.

The PLC incorporates our new compact industrial computer, which operates off LabView software. ( The reliability of the industrial computer is 35KHrs MTBF. ) We first introduced this to our production systems 12 months ago, and we are now offering it as upgrade package to our legacy customer base.

It is a programmable PLC (programmable logic controller) written in machine code, which makes software more reliable. Part of Trion’s philosophy is simplicity and the new PLC system continues that philosophy by introducing simpler point-to-point interconnects which facilitates a decrease in installation time and an increase in ease of maintenance.

Click Here to Close