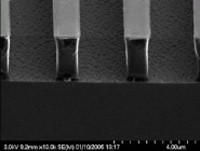

This BCl3/Cl2 based process is a very chemical etch. Pure aluminum, by itself, etches readily in a Cl2 plasma. However, a native oxide layer covers all aluminum films, so BCl3 is added to increase the amount of sputtering and to scavenge the oxygen in the aluminum oxide layer. A burst step may be required to break through any native oxides that may have formed on the surface. Processes have been developed with etch rates of over 2,000 Å /min

Using a low pressure ICP-based process involving chlorine and argon is sufficient to etch this metal at room temperature at rates of up to 700 Å /min. Higher temperature will increase the rate.

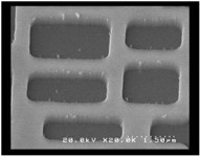

Copper processing has specific challenges with respect to etching because it requires low volatility for CuClx (for chlorine etching) species, it has a high oxidation rate, and it does not self-passivate. The industry has conducted many tests to address these issues, and Trion has developed a “formula” that works. This Chlorine based process requires the sample to be heated above 150C and can produce etch rates of over 5,000 Å /min.

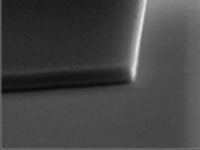

This Chlorine based process will etch Chrome controllably. The process is dominated by both a kinetic, and reactive mechanism at rates of over 800 Å /min. There is a wide process window under optimized process conditions as we see no trace of either photo resist burning or any visible roughness in the form of micro-masking.

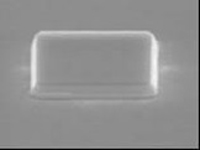

Using a low pressure ICP-based process involving chlorine and argon is sufficient to etch this metal at room temperature at rates over 1100 Å /min. Higher temperature will increase the rate if using an oxide mask.

Platinum with 3000 Å SiO2 hard mask. Argon, Cl2, RIE turbo pump, heated chuck, rate ~1000 Å/minute. Temperature – 90C, Selectivity (Pt:SiO2) = 20:1

Aluminum Etch

Application: Failure Analysis; Metal Etching Aluminum

Trion Tool: Minilock-Phantom RIE or Oracle

“Etching was done using Boron Tri-chloride (BCl3) and Chlorine (Cl2) gas …”

Aluminum Etch

Application: Failure Analysis; Metal Etching Aluminum

Trion Tool: Minilock-Phantom RIE

“Aluminum etching is one of the most difficult processes. However, if done correctly very good etch results can be obtained. A good starting recipe for more uniform but isotropic etching of the Al is: …”

Copper Etch using Trion Minilock-Phantom RIE

Gold and Platinum Etch using Trion Minilock-Phantom RIE

Metal Etch using Minilock-Phantom RIE ICP

Planar Deprocessing Of Advanced VLSI Devices

by K. Wills, Texas Instruments

Application: Failure Analysis; Dielectric Etching; Metal Etching Copper

Reliability Issues And Advanced Failure Analysis Deprocessing Techniques For Copper/Low-K Technology

by H. Wu, J. Cargo, C. Peridier and J. Serpiello (Agere Systems, IC Quality Organization, Product Analysis Lab, Allentown, PA)

Application: Failure Analysis; Dielectric Etching; Metal Etching Copper

Trion Tool: Phantom RIE